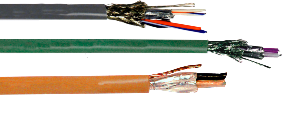

| INSTRUMENTAL SIGNAL CABLES : | |

We at Thermotech manufacture speciality cables for instrumentation applications .

Instrumentation cables have very deserve application For the last two decades, we

have been manufacturing instrumentation cables require in process industries in the

area of oil exploration cement paper, steel, power generation etc. These industries

use speciality cables conforming to various world standards. There are no special

standards in India for instrumentation cables such as BS 5308, ENI, IEC, 189, DIN

etc. We have the capability to manufacture cables to meet any stringent specifica-tions, or combinations of specifications.. CONDUCTOR :Various sizes of copper conductors are

drawn on automated on-line annealing

wire drawing machine to exacting material

standards. They are further tinned , if

required and bunched on world class

high-speed bunching machines. CONDUCTOR :Various sizes of copper conductors are

drawn on automated on-line annealing

wire drawing machine to exacting material

standards. They are further tinned , if

required and bunched on world class

high-speed bunching machines. |

|

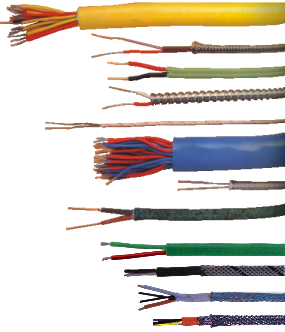

INSULATION :The conductors are then insulated on high speed world class extrusion system. We can extrude various type of material such as PVC, Polyethylene, Teflon, Silicon etc. These insulated core can be printed with numbers for identifications. The extrusion has on line nstrumentation which check for some of physical and electrical parameters of the insulated cores.. PAIRING & SCREENING :The insulated core are paired to various lay lengths according to the specifications on high speed twisting machine. It also ensure electrical integrity during the twisting process. These machine also ensure a proper on-line screening as per customer, specifications. We also manufactured cables with copper braided screens which are anufactured on world class high speed machines. ARMOURING :The inner sheathed cables is then armoured to customer specification for mechanical protections. We can offer armour with various types of high - quality hot-dipped zinc galvanized wires or strips on high- speed amouring machines having special processing technique Usually armouring is a bottleneck area in traditional cable manufacturing but not so at thermocab Cables.. |

|

| THERMOCOUPLES EXTENSION & COMPENSATING CABLES : | ||

| Thermocouple Extension or Compensating Cables are required to transfer reference junction to the control

room. The construction of Thermo couple cable is in principle similar to the instrumentation cables. However

the characteristic are tested against ANSI, MC 961 or IS 8780. The colour codes are also generally

conforming to the above standards.

INSULATION :The compensation cables are cores are insulated with : |

|

|

|

SHEATHING :(a) Flames - proof compounded asbestos fabric braiding, or SHIELDING :Plain or tinned Braided copper wire shielding is provided alternatively it may be heat resistant aluminized .polyester foil called mylar tope in parallel connection of one drain wire of tinned copper. Armouring is generally provided of galvanized steel wire. But any other suitable wire may be used as per user's specifications.. |

|

ARMOURING :The pattern selected depends upon weather protection is required against moisture

( attracted by asbestos fibers ) mechanical damage of both A further decisive factor

is how the cables are run, fixed, trailing and in the former case whether surface

run or laid in conduit.. |

||

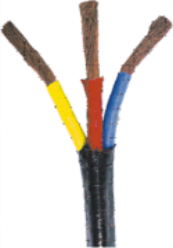

| HIGH TEMPERATURE POWER CABLES FOR SPONGE IRON PLANTS : | |

These cables are designed to work with high current loads at high temperature environment conditions, such as wiring of furnace, heaters, ovens and industrial wiring under harsh working conditions . Conductors are made of fine multi strand Bare/Silver Plated copper strands. PTFE insulated / Silicon for 600 V / 1000 V working voltage grade, having suitable insulations this thickness, which can bear the mechanical load of heavy conductor, overall fibre glass braided & silicon varnished to provide surface protection to inner dielectric for extra mechanical stability. It can be further braid armoured with stainless steel wire or Tin plated copper wire. MULTICORE POWER CABLES : PTFE insulated Power Multicore cables with 2 Core, 3 Core & 4 Core are available basic Cores are insulated with PTFE for 600 Vworking grade laid up & PTFE Jacketed overall fibre glass braided with silicon varnish or stainless steel braided for mechanical protection, However combination of both FG & SS can be also be given. |

|

1. CORE CONDUCTOR : Stranded high conductivity electrolytic grade annealed bare

nickel / silver plated copper.

|

|

| SILICON RUBBER CABLE: | |

CONSTRUCTION : Voltage grade, Size range & specification: Cable with other protective sheath such as silicon, neoprene & CSP sheath, wire braid or single wire or

strip armoured / screened also can be supplied . |

|